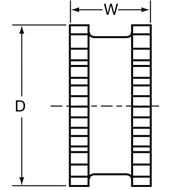

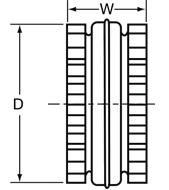

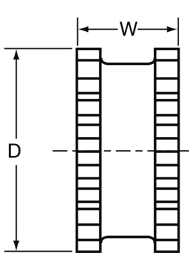

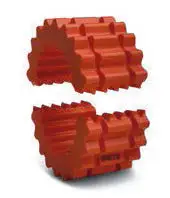

Sleeve Tbwood Coupling Supplier in China

We build our position as a leading Sleeve couplings Supplier in China. Who Manufacture, Supply and Export best quality of Sleeve couplings at reasonable price. Sleeve couplings are commonly used in industrial machinery such as conveyors, pumps, compressors, and mixers. They are used to connect the motor shaft to the driven machinery. Sleeve couplings are also used in agricultural machinery such as tractors, cultivators, and harvesters to transmit power between the engine and the driven machinery. Sleeve couplings are used in marine propulsion systems to connect the engine to the propeller shaft. They are also used in other marine applications such as winches, pumps, and generators. Sleeve couplings are used in the automotive industry to connect the engine to the transmission system. They are also used in other automotive applications such as steering systems and power take-off units. Sleeve couplings are used in power generation applications such as generators and turbines to connect the engine or turbine shaft to the generator shaft. Sleeve couplings are used in heavy-duty mining and construction machinery to connect the engine or motor to the driven machinery. Sleeve couplings are versatile devices that are used in a wide range of industries to connect shafts and transmit power between them.