GR hubs are available in Aluminium, Cast Iron and Steel Material. GR sizes from 19 to 28 are made from Aluminium Alloy & Steel material. GR sizes from 38 to 90 are made from Cast Iron & Steel Material.

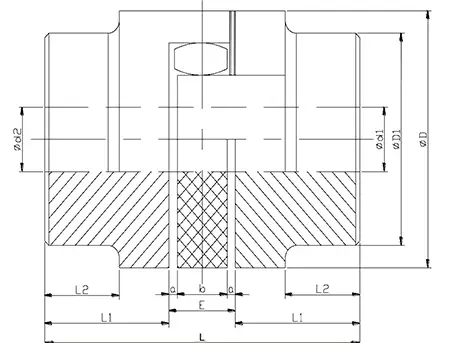

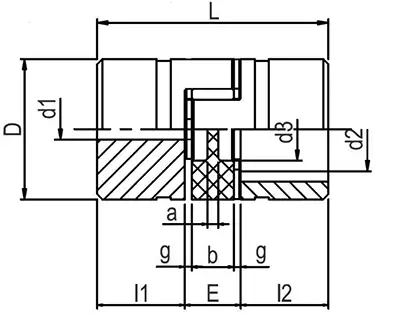

GR hubs are manufactured with high precision machining. The jaws are machined with concave shape and entry chamfer for easy assembly. The concave shape in jaws of hub and the convex shape on the polyurethane spider allows for better angular, parallel and axial misalignment.

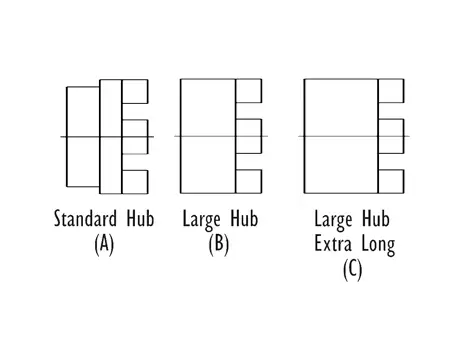

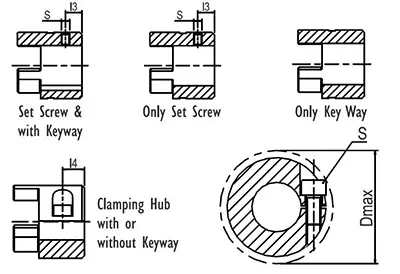

These hubs are available in un-bored, pilot bored, finish bore & key-ways, and with different styles of clamping arrangements as per customer requirements.